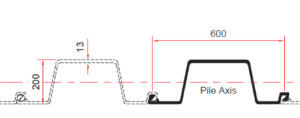

NS-SP-J – Non-Deadspace Steel Sheet Piles (Zero Piles)

Close-proximity (zero dead space) installation Zero-Piles can be installed in close proximity to existing structures, permitting construction of retaining walls abutting site boundaries resulting in “zero dead space” and making the maximum use of the site area leading to significant value addition to any land development. 100% interlock integrity.

As interlocks are located on the outermost side of the wall, there is no need to consider reduction of sectional properties due to the slip on interlocks, which permits economical design. Cost-saving and Work-shortening of Temporary Work Compared with the conventional steel sheet pile for temporary work with the effective width of 400mm, Zero-Piles have the

effective width of 600mm. This makes it possible to reduce the

water tightness.

Sectional Properties

| Type | Effective width W (mm) | Effective height h (mm) | Thickness t (mm) | Per pile | Per 1 m of pile wall width | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sectional area (cm²) | Moment of inertia (cm⁴) | Section modulus (cm³) | Unit mass (kg/m) | Sectional area (cm²/m) | Moment of inertia (cm⁴/m) | Section modulus (cm³/m) | Unit mass (kg/m²) | ||||

| Zero-Pile | 600 | 200 | 13.0 | 111.2 | 7,250 | 705 | 87.3 | 185.3 | 12,090 | 1,175 | 145 |

Material Quality

| Classification | Grade | Chemical composition (%) | Ceq. (%) | |||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | N | |||

| Weldable hot rolled steel sheet piles JIS A5523 |

SYW295 | 0.18 max. | 0.55 max. | 1.50 max. | 0.04 max. | 0.04 max. | 0.0060 max. | 0.44 max. |

| SYW390 | 0.45 max. | |||||||

Note: Ceq. = C + Mn/6 + Si/24 + Ni/40 + Cr/5 + Mo/4 + V/14

Mechanical Properties

| Classification | Grade | Yield Point (N/mm²) |

Tensile Strength (N/mm²) |

Test Specimen | Elongation (%) |

Charpy V-notch toughness J | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Type & Direction of specimen | Test Temp. (°C) | Standard 10x10mm | 10×7.5mm | 10x5mm | ||||||

| Weldable hot rolled steel sheet piles JIS A 5523 |

SYW295 | 295 min. | 450 min. | No.1A | 18 min. | V notch in rolling direction | 0 | 43 min. | 32 min. | 22 min. |

| No.14B | 24 min. | |||||||||

| Weldable hot rolled steel sheet piles JIS A 5523 |

SYW390 | 390 min. | 490 min. | No.1A | 16 min. | V notch in rolling direction | ||||

| No.14B | 20 min. | |||||||||

Note: Chemical composition and mechanical properties conform to JIS A5523-2012. N is shown by total in accordance with section 5, Note 2 of JIS A5523-2012. Grade of S355GP (EN 10248 Part 1) is also available upon request.

Tolerance of Shapes and Dimensions

| Item | Tolerance |

|---|---|

| Full width | + 10 mm / – 5 mm |

| Height | ± 4% |

| Thickness Under 10 mm | ± 1.0 mm |

| Thickness 10 mm and over to 16 mm excl. | ± 1.2 mm |

| Thickness 16 mm and over | ± 1.5 mm |

| Length | + Not specified / – 0 |

| Deflection 10 m and under in length | Full length (m) × 0.12% max. |

| Deflection Over 10 m in length | (Full length – 10 m) × 0.10% + 12 mm max. |

| Camber 10 m and under in length | Full length (m) × 0.25% max. |

| Camber Over 10 m in length | (Full length – 10 m) × 0.20% + 25 mm max. |

| Difference in vertically cut section | Within 4% of width |

| Mating joint angle | ≥ 4° |

Deviation Angle

# Zero-Piles can be interlocked with some of the U-type sheet piles. The compatible types for interlocking depend on the site conditions. Please consult Nippon Steel & Sumitomo Metal for details.

Note:

1. Tolerance of shapes and Dimensions conform to JIS A5523-2012

2. “Deflection” stands for the deviation from the plain parallel to the sheet pile wall and “Camber” stands for the deviation from the plain for vertical to the sheet

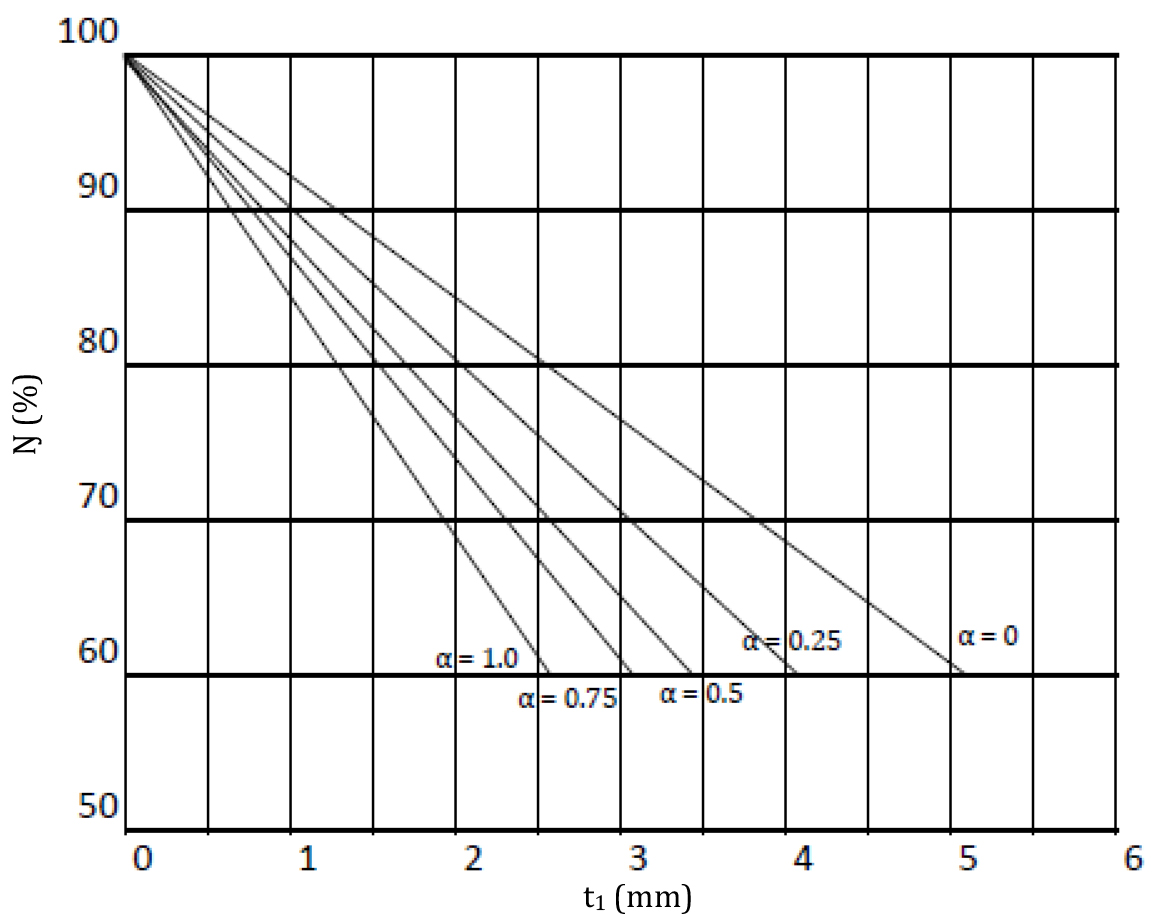

Sectional Properties after Corrosion

| Type | Sectional Properties without corrosion loss | Sectional Properties with 1 mm corrosion loss per side | |||

|---|---|---|---|---|---|

| Io (cm⁴/m) | Zo (cm³/m) | ŋ (%) | I (cm⁴/m) | Z (cm³/m) | |

| Zero-Pile | 12,090 | 1,175 | 85 | 10,300 | 999 |

Notes on Sectional Properties and Corrosion Loss

Io, Zo : Moment of Inertia and Section Modulus without corrosion loss

ŋ : Reduction ratio after corrosion

I, Z : Moment of Inertia and Section Modulus after corrosion

Steps to calculate sectional properties after corrosion:

Assume corrosion rate and lifetime of the facility, and calculate the corrosion loss of the marine side (t₁, mm) and that of the land side (t₂, mm).

Calculate corrosion loss rate ⍺ (= t₂ / t₁).

By using the corrosion loss of the marine side (t₁, mm) and the corrosion loss rate (⍺), obtain the reduction ratio of sectional properties (ŋ) from the reference graphs.

Calculate the sectional properties after corrosion loss (Z and I) by multiplying the sectional properties before corrosion loss (Zo and Io) by the reduction ratio ŋ.

Section modulus: Z = Zo × ŋ

Moment of Inertia: I = Io × ŋ

Definitions:

ŋ : Reduction ratio of sectional properties after corrosion (%)

t₁, t₂ : Corrosion loss of marine side and land side (mm)

⍺ : Corrosion loss rate (⍺ = t₂ / t₁)

Note: Only the illustrated ranges are effective in the referenced graphs.

NS-SP-J - Non-Deadspace Steel Sheet Piles (Zero Piles)

Efficient steel piles designed for strong soil retention and minimized space loss.